How Can A Schedule 10 Steel Pipe Thickness Chart Assist Engineers In Selecting Appropriate Materials?

When selecting materials for construction or engineering tasks, knowing the properties of pipes is crucial for ensuring protection, stability, and performance. One of the maximum crucial factors to not forget is the pipe wall thickness, which determines how properly the pipe can face up to the strain and environmental strain.

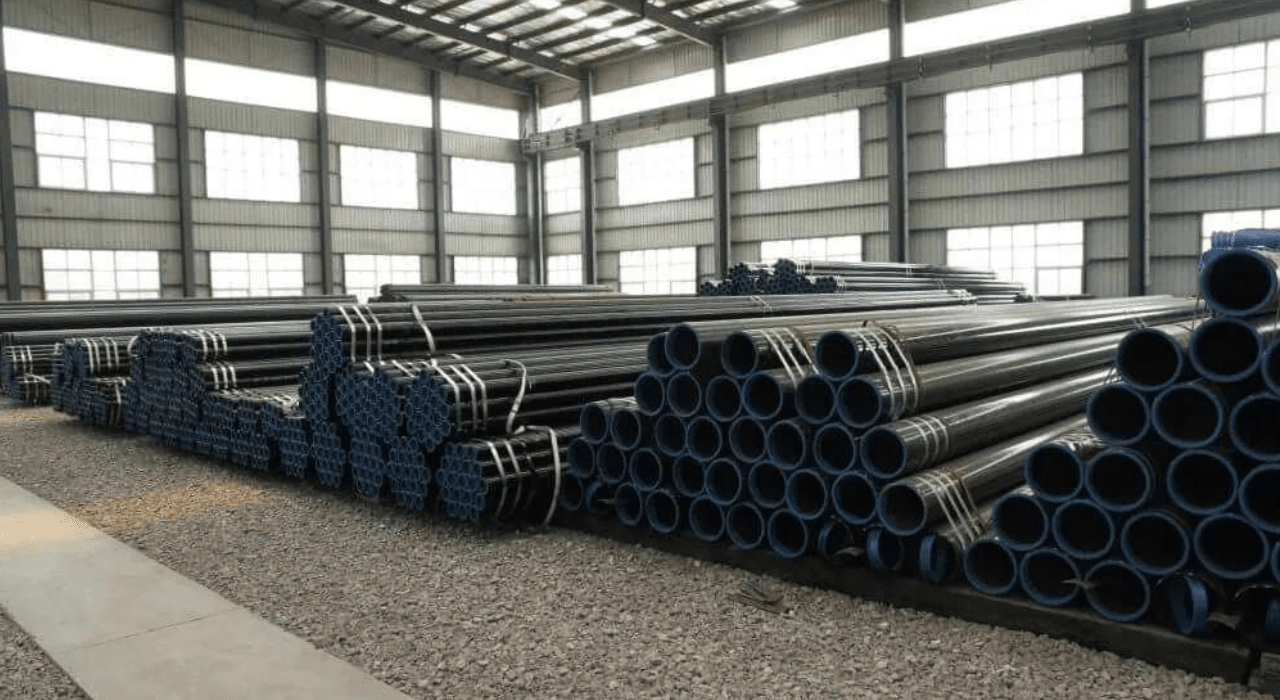

Schedule 10 steel pipes, with their highly thin partitions, are frequently selected for low-strain programs such as HVAC systems, water lines, and business projects where lightweight substances and cost performance are key. A Schedule 10 steel pipe thickness chart gives crucial records of approximate pipe dimensions, permitting engineers to accurately assess whether a specific pipe meets the structural and operational requirements of their challenge.

By referencing this chart, engineers can examine wall thicknesses across different pipe schedules, making sure the selected material will perform correctly without adding pointless weight or cost. The schedule 10 steel pipe thickness-wall thickness chart also plays a vital role in assembly enterprise standards, regulatory compliance, and long-term stability, making it a critical tool for professionals tasked with optimizing cloth choices in various programs.

Schedule 10 Steel Pipe Thickness Chart Assisting Engineers in Selecting Appropriate Materials

While selecting materials for an undertaking, engineers rely heavily on technical charts and specs to make informed choices. One such device is the Schedule 10 steel pipe thickness chart, which gives vital statistics on pipe dimensions. This article explores how those charts can help manual engineers select the right materials, factoring in elements like pipe power, compatibility with fluids, and standard structural integrity.

Importance of Wall Thickness in Structural Integrity

The wall thickness of a pipe determines its ability to withstand inner and outside pressures. Engineers assess this feature to make sure that the selected material can withstand working situations, together with high temperatures, fluctuating pressures, or corrosive fluids. A Schedule 10 pipe, being quite skinny, might be perfect for applications where excessive pressures are absent, however, where retaining a strong structure is still vital. The chart allows engineers to quickly reference those specifications and make choices that uphold the integrity of the whole device.

Material Selection Based on Application Needs

Special engineering initiatives have varying needs regarding fluid dynamics, temperature tolerance, and environmental situations. The Schedule 10 steel pipe thickness chart helps engineers pick a pipe material that suits these criteria. For instance, a Schedule 10 pipe may be more suitable for HVAC systems, irrigation, and different low-pressure applications. Through referencing the chart, engineers can compare different schedules and materials to discover an answer that meets performance requirements whilst also being value-effective.

Cost Efficiency and Weight Considerations

One of the essential reasons engineers might choose a Schedule 10 pipe is its lower weight and cost compared to pipes with thicker partitions. Due to the fact Schedule 10 pipes are thinner, they require less material, making them lighter and cheaper to fabricate, ship, and deploy. The thickness chart plays a vital function in balancing value and efficiency. While thicker pipes like those in Schedule 40 or 80 may additionally provide extra strength, they arrive at a better price point. Engineers use the chart to assess how skinny they could pass without compromising safety or overall performance.

Compatibility with Corrosive Environments

In many industries, the pipes are exposed to corrosive materials, whether from chemical compounds, gases, or environmental factors like moisture. Engineers must carefully recollect the material’s resistance to corrosion whilst deciding on a pipe. The Schedule 10 steel pipe thickness chart can help manual this selection. If a pipe is too thin, it can corrode quickly, leading to leaks or pipe disasters. The chart permits engineers to assess whether or not a schedule 10 pipe, whilst blended with sure defensive coatings or corrosion-resistant materials, will be carried out efficiently in such conditions.

Flexibility in Design and Installation

Schedule 10 pipes, being lighter and thinner, provide extra flexibility in installation and layout. Engineers need to consider how smooth the material will be to address, bend, or weld at some stage in construction. The thickness chart allows us to figure out whether the material’s flexibility might be useful for a particular undertaking. For instance, in tight spaces where maneuverability is key, a thinner pipe might be favored. This adaptability can also result in faster installation instances, decreasing exertion prices, and enhancing normal undertaking efficiency.

Ensuring Safety and Performance

Protection is constantly a pinnacle challenge in engineering projects. The use of the Schedule 10 steel pipe thickness chart lets engineers ensure that their material picks do not compromise the safety of the tool. With the aid of reviewing the chart, engineers can verify that the pipe will preserve up below the anticipated stresses and loads, preventing injuries, leaks, or different failures. This is mainly important in industries like oil and gasoline, chemical processing, and creation, where a failure could have catastrophic effects.

Conclusion

The Schedule 10 steel pipe thickness chart is a useful device for engineers, assisting them in picking out the proper substances for an extensive variety of applications. From ensuring structural integrity to balancing price efficiency, the chart gives crucial records that aid in decision-making. By carefully analyzing wall thickness, cloth compatibility, and regulatory requirements, engineers can use this chart to guide their initiatives closer to fulfillment, ensuring each is safe and performing while adapting to new enterprise developments.